Project development.

We design complete metal projects, covering everything from architectural components to industrial products. Each project is approached with attention to structure, function, and visual clarity, ensuring that every part fits within the broader purpose of the final result.

The process moves from early sketches and concept studies to technical drawings and three dimensional development. Our work in industrial and mechanical design brings together form, function, and construction logic, defining how each element is shaped, assembled, and integrated into the overall system.

Laser cutting and press brake.

We offer sheet metal laser cutting and CNC press brake bending for aluminum, steel, stainless steel, and other commonly used alloys. These services are suited for both custom parts and production runs, covering a wide range of applications in construction, industrial equipment, and product manufacturing.

Welding.

Welding services are available for steel, stainless steel, and aluminum components, using MIG and TIG processes based on project needs. Suitable for both structural assemblies and detailed work, from individual pieces to small production runs.

Finishings.

Finishing services include deburring, grinding, brushing, surface preparation, and powder coating, applied to aluminum, steel, and stainless steel parts across different project scopes.

Assembling and QA/QC.

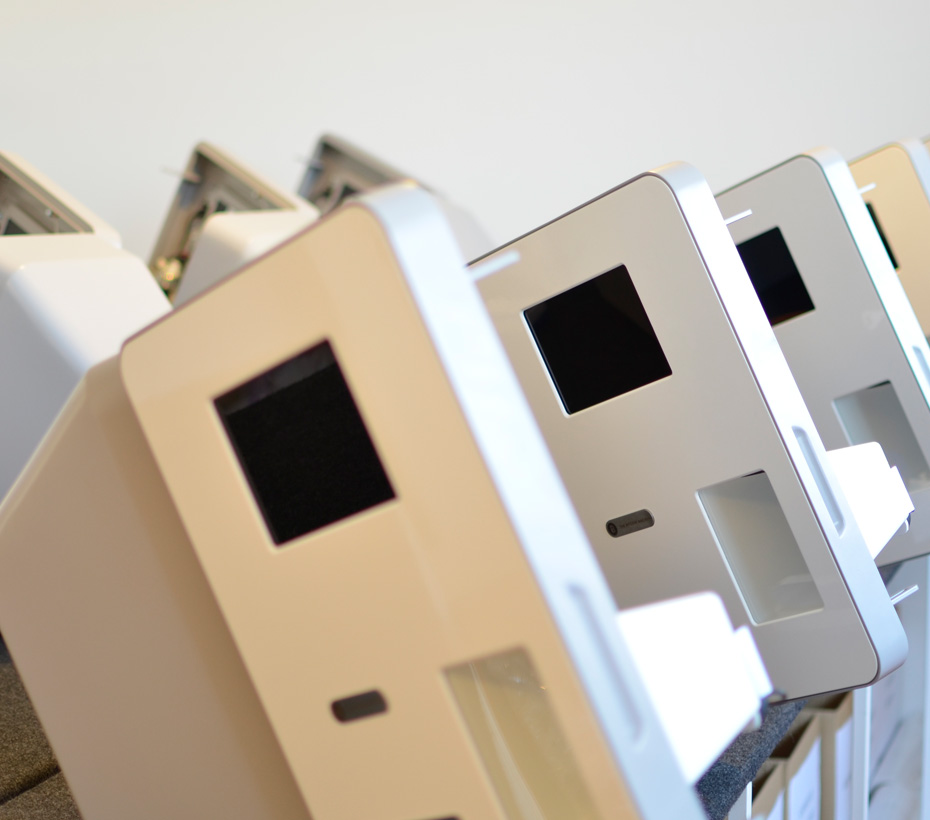

Assembling services cover the integration of mechanical structures with electronic components and electrical systems. Each project follows defined technical specifications and includes quality control procedures and functional testing before completion.

Our work.

We focus on refined details and seamless execution, bringing every element together to deliver clean, precise, and carefully built results.

Contact Us.

Rua Amândio Ferreira da Silva, 117

4785-420 Trofa, Portugal

Phone: +351 252 418 185

Email: info@moobo.works

Copyright © 2025 Moobo.works

All rights reserved.